Frankford Elevated News (1915-1927)

Frankford Elevated News (1915-1927)

Electric Railway Journal · Various Issues, 1915-1927

READY FOR SERVICE. Some of the 50 large new all-steel cars going into operation on the Frankford Elevated Railway, Philadelphia... [Westinghouse advertisement, April 15, 1922. See below.]

A collection of short news articles about Philadelphia's Frankford Elevated, from various issues of Electric Railway Journal.

June 26, 1915.

The Philadelphia Transit Loan. -- The surveys committee of Councils of Philadelphia has reported favorably a bill directing A. Merritt Taylor, director of city transit, to contract for the relocations and the rebuilding of certain sewers in Philadelphia in the interest of the proposed Broad Street subway and Frankford elevated line. The report of the sewer bill was followed by the passing of a resolution providing for additional stated meetings of both chambers of Councils on June 23 and 30 to act on the bills appropriating the money and authorizing contracts to be let for an immediate start on the work of transit improvement.

July 3, 1915.

The Philadelphia Transit Ordinance. -- By unanimous vote the Common Council of Philadelphia, Pa., has passed the ordinance authorizing the $6,000,000 transit loan. The finance committee's plan is to have the loan ordinance transmitted to the Mayor as soon as it is concurred in by Select Council. Immediately upon being advised that the ordinance has been approved by Mayor Blankenburg, the finance committee will report the appropriation ordinance, which will be passed by both chambers. The committee proposes to allot $3,000,000 for preliminary work on the Broad Street subway and $3,000,000 to the Frankford Elevated line.

July 10, 1915.

PHILADELPHIA TRANSIT LOAN APPROVED. The Councils of Philadelphia, Pa., on July 1 by unanimous vote passed ordinances appropriating the $6,000,000 transit loan to the Department of City Transit and authorizing Director of City Transit A. Merritt Taylor to let contracts and start work immediately on the Broad Street subway and the Frankford elevated. The ordinances allotted $3,000,000 of the loan for each of these projects. Actual construction work on both projects will be started on Sept. 13. Mr. Taylor says that if there is no delay in making the loans available, the entire Broad Street subway can be completed in thirty-two months and the Frankford elevated road within two years. [...]

Advertisements were scheduled to appear in the papers on July 8, inviting bids for the construction of the foundations for the Frankford elevated line, between Callowhill Street on the south and Unity Street on the north. Bids for this work will be opened on Aug. 16. The specifications call for actual construction to be commenced on Sept. 13, and for the contract to be completed within eight months. Advertisements will appear in the papers on July 26 inviting bids for the construction and erection of the steel work for the section of the Frankford elevated line, extending from Callowhill Street on the south to Unity Street on the north. Bids for this work will be opened on Aug. 23. The specifications call for the erection of the steel work to be commenced on Dec. 1, 1915, and for the contract to be completed within one year.

July 31, 1915.

Philadelphia's application for a certificate of public convenience, the next step toward building the Broad Street subway and the Frankford elevated, was argued on July 26 in Harrisburg before the Pennsylvania Public Service Commission. Appearing in opposition to granting the certificate were E. A. Ballard, chief counsel Philadelphia Rapid Transit Company; Ruby R. Vale, counsel for D. E. Dallam, whose suit for an injunction was described in the Electric Railway Journal of July 24; and Charles L. Fluck, of the Northwest Business Men's Association. City Solicitor Ryan was present on behalf of the municipality, and A. Merritt Taylor, Director of City Transit, was the sole witness heard.

September 16, 1916.

Philadelphia, Pa. -- Following the announcement by Mayor Smith that a $10,000,000 portion of the new city loan is to be floated by a bond issue Nov. 1, Director Twining, of the department of city transit, announced on Sept. 7 that estimates for work on three sections of the huge subway loop would be called for in a few months and that the contracts would be awarded in January. It is estimated that about one-quarter of this $10,000,000 will be devoted to transit and port improvement purposes. According to Director Twining, the major portion of the 1917 construction work will have to do with the subway loop and the Frankford elevated. The preliminary plans for this work will be passed upon by the Public Service Commission engineers within a week or so. After this the department will immediately proceed with the plans in detail. Director Twining, speaking of the loop contracts, explained that those for the Eighth Street, the Locuot and Arch Streets sections would be awarded first, while the Broad Street section, which involves the more difficult engineering problems, will be awarded two or three months later. Director Twining believes the Frankford elevated will be completed as far as Ridge Street by the end of 1917. Several other contracts, principally for work in the City Hall section, will be awarded some time at the end of the present year, it is said. This will probably include the City Hall station.

November 11, 1916.

In March Councils called an election for the purpose of authorizing an increase in the city's debt in the amount of $6,000,000, to be devoted to the construction of the Broad Street subway and the Frankford elevated railway. The vote being affirmative, $3,000,000 was appropriated for each of these lines, contracts were let and work was begun on certain sections during the remainder of the year.

November 25, 1916.

Philadelphia, Pa. W. S. Twining, director Department of City Transit, has filed an application for a certificate of convenience to permit the construction of a station on the Frankford Elevated line at Huntingdon Street and Kensington Avenue. This station will be midway between the stations at Dauphin and York Streets and the Somerset Street Station.

February 3, 1917.

Philadelphia, Pa. The installation of a trackless trolley to serve the Byberry section has been recommended by M. J. Ryan, Public Service Commissioner, in connection with plans for the extension of the Frankford elevated line to this point.

March 31, 1917.

Philadelphia, Pa.-- Work on the Frankford elevated line of the city's new high-speed transit system has been resumed. The superstructure is completed to Ontario Street, and work has been begun there. Work was stopped in December last because weather conditions would not permit the laying of concrete bases on which the supporting columns of the L structure rest. This concrete work, for which Vare Brothers have contracts, will be begun at once, and the McClintie-Marshall Company, contractors for the structural steelwork, have notified Director Twining of the City Transit Department that they will resume the erection of steel column supports by April 2.

April 14, 1917.

The Public Service Commission of Pennsylvania has refused to grant the city of Philadelphia authority to proceed with the construction of the new Broad Street subway, the central delivery loop, the Parkway-Roxborough subway-elevated line, and the high-speed surface line to Byberry. The only favorable action taken was on the extension of the Frankford elevated to Rhawn Street.

April 14, 1917.

Philadelphia, Pa. -- Sealed proposals wall be received by the Department of City Transit, Philadelphia, Pa., William S. Twining, director, until 12 o'clock noon, on April 17, for additional steel superstructure and appurtenant work to provide station platforms on the Frankford Elevated Railway at Huntingdon Street (Contract No. 520). Copies of plans and specifications may be obtained upon deposit of $10, to be refunded upon return of plans.

April 21, 1917.

Philadelphia, Pa.-- The city of Philadelphia has received a certificate of public convenience from the Public Service Commission of Pennsylvania for the construction of the northern end of the Frankford elevated line from Dyre to Rhawn Street. The commission has deferred considering applications for certificates authorizing the remainder of the proposed high-speed lines until the present legislative session is concluded.

April 28, 1917.

Philadelphia, Pa. -- Sealed proposals will be received by the Department of City Transit, Philadelphia, until May 1 for 168 column foundations in Frankford Avenue from Unity Street to Dyre Street, Frankford Elevated Railway, contract No. 503. Copies of plans and specifications may be obtained upon deposit of $10, to be refunded upon return of plans.

May 19, 1917.

Philadelphia, Pa. -- Sealed proposals will be received by the Department of City Transit, Philadelphia, Pa., William S. Twining, director, until May 22, for contract No. 521, including concrete track floor, cast-iron and steel floor drains and reinforced concrete slab footwalks for the Frankford Elevated Railway from Callowhill to Indiana Streets, about 15,680 lineal feet of structure; contract No. 522, concrete track floor, cast-iron and steel floor drains and reinforced concrete slab footwalks for the Frankford Elevated Railway from Indiana to Dyre Streets, about 15,000 lineal feet.

July 14, 1917.

Philadelphia, Pa. -- Bids opened for the construction of ten stations on the Frankford Elevated line by Director Twining of the Department of City Transit on July 10 were so far above the estimates upon which the department had based its appropriations for the cost of the work that the bids were discarded. Hence new estimates will have to be made and bids readvertised. There were but two bidders for the construction of the ten buildings, and the higher of these bids was $550,000 and the lower $510,000. Bids for the electrical and plumbing installations were well within the department's estimates but were invalidated by the necessity of drawing up entirely new specifications.

August 11, 1917.

The Frankford elevated structure which is about two-thirds finished is to cost $7,400,000. This amount represents just the bare steel structure. Several million dollars will have to be spent for track and accessories, rolling stock and equipment. On the subway, contracts aggregating $14,000,000 have been awarded for construction work. The total cost of construction is estimated from $50,000,000 to $65,000,000. Only a small section is actually under construction, the amount of the contract covering it being about $3,000,000.

August 18, 1917.

Philadelphia, Pa. -- Sealed proposals will be received by the Department of City Transit, Philadelphia, William S. Twining, director, for the following work appurtenant to the Frankford Elevated Railway: Contract No. 524 -- Steel frame work and railings, concrete floors and parapets, side inclosures, roofs, drain gutters and spouts for ten station platforms and connecting passages or foot bridges between station platforms and station buildings at Allegheny Avenue, Tioga Street, Torresdale Avenue, Rhawn-Church Streets and Orthodox-Margaret Streets.

February 9, 1918.

Philadelphia, Pa. Sealed proposals will be received by the Department of City Transit, William S. Twining, director, until 12 o'clock noon on Feb. 14 for the following work appurtenant to the Frankford Elevated Railway: Contract No. 541 Plumbing installations in station buildings at Torresdale Avenue and Tioga Street; Contract No. 542 Electric installations in station buildings at Torresdale Avenue and at Tioga Street. Copies of plans and specifications may be obtained upon deposit of $10, to be refunded upon return of plans.

March 2, 1918.

Philadelphia, Pa. Sealed proposals will be received by the Department of City Transit, William S. Twining, director, until 12 o'clock noon on March 5 for the following work appurtenant to the Frankford Elevated Railway: Contract No. 529 Furnishing and delivering cast-iron fillet brackets for columns in Frankford Avenue between Church Street and Dyre Street. Sealed proposals will also be received until 12 o'clock noon on March 12 for the following work: Contract No. 537 Erection of brick and reinforced concrete station buildings at the northeast and southwest corners of Kensington and Allegheny Avenues, including the removal of existing buildings on these sites. Contract No. 538 Erection of brick and reinforced concrete station buildings at the southwest and southeast corners of Kensington Avenue and Somerset Street, including the removal of existing buildings from these sites. Copies of plans and specifications may be obtained upon deposit of $10, to be refunded upon return of plans.

April 13, 1918.

Philadelphia, Pa. Mayor Smith of Philadelphia on April 4 made a plea to the Government for permission to complete the Frankford elevated line, after a conference at which he received reports from the heads of the city departments giving the status of all public works under construction which are affected by Secretary McAdoo's work stoppage order. Copies of the reports, together with a detailed account by W. S. Twining, Transit Director, of the work on the elevated line and the necessity for its completion now, were forwarded to the capital-issues committee of the Treasury Department, which has charge of the matter.

March 15, 1919.

Philadelphia, Pa. -- Sealed proposals will be received by William S. Twining, Director Department of City Transit, until March 25 for the construction of 68 column foundations of concrete in Front Street from above Arch Street to Callowhill Street, Frankford Elevated Railway, contract No. 500. Plans and specifications may be obtained at the office of the Department, Mershon Building, upon deposit of $10, which will be refunded upon return of the plans.

April 12, 1919.

Philadelphia, Pa.-- Bids were recently received by the Department of City Transit for the construction of 68 column foundations of concrete in Front Street from above Arch Street to Callowhill Street, for the Frankford elevated line. The lowest bidder was the Brown-King Construction Company, Philadelphia, Pa., at $32,058. Sealed proposals will be received by William S. Twining, director of the Department of City Transit, until April 22 for furnishing and erecting the steel superstructure for a continuation of the Frankford Elevated Railway in Front Street, from near Arch Street to Callowhill Street.

April 26, 1919.

Philadelphia, Pa. -- Sealed proposals will be received by William S. Twining, director of the Department of City Transit of Philadelphia until April 29 for the following work appurtenant to the Frankford Elevated Railway: Contract No. 551 -- Erection of brick, steel and reinforced concrete station buildings at the northeast and southwest comers of Kensington and Allegheny Avenues, including the removal of existing buildings on these sites, and Contract No. 552 -- Erection of brick, steel and reinforced concrete station buildings at the southwest and southeast comers of Kensington Avenue and Somerset Street, including the removal of existing buildings from these sites. Copies of plans and specifications may be had upon deposit of $10 for each set of plans, which will be refunded upon return of plans.

May 3, 1919.

Philadelphia, Pa. A contract has been awarded by the Department of City Transit to the North American Railway Construction Company, Chicago, for the first six miles of the proposed Frankford-Byberry line. The contract price is $370,892. Bids were opened on April 22 for the construction of the superstructure on the Frankford elevated line from Callowhill Street south to within a short distance of Arch Street. The lowest bidder was the Phoenix Bridge Company, Phoenixville, Pa., at $176,399.

May 24, 1919.

Philadelphia, Pa. Sealed proposals will be received by William S. Twining, director Department of City Transit, for the following work appurtenant to the Frankford Elevated Railway: Contract No. 564 Erection of brick, steel and reinforced concrete station buildings at the northeast and southwest corners of Kensington and Allegheny Avenues, including the removal of existing buildings on these sites. Contract No. 565 Erection of brick, steel and reinforced concrete station buildings at the southwest and southeast corners of Kensington Avenue and Somerset Street, including the removal of existing buildings from these sites. The plans are modifications of those issued for bids opened April 29 and rejected. Copies of plans and specifications may be obtained upon deposit of $10, to be refunded upon return of plans.

June 21, 1919.

Transit Director Urges Legislation. To obtain funds to complete the Frankford elevated line in Philadelphia, Pa., Director Twining, of the department of city transit, urges passage of the Salus bill by the Legislature. This measure would permit the transfer of funds which could be used for completion of the Frankford line on June 13. Director Twining said the bill was in the hands of a sub-committee of the House, and that unless the measure should be reported immediately with a favorable recommendation, it would not be possible to pass it.

December 13, 1919.

Ordinances Introduced in Council. Mr. Mitten's program was embodied in a series of ordinances recently introduced in the City Council and now pending before that body, as announced previously in the Electric Railway Journal. The plan calls for the release of the company from the annual payment of $785,000 for street paving. In return for which the company agrees to abolish the 3-cent charge for exchange tickets, except in certain sections of the city, where the transfer privilege would be done away with. [...] Mr. Twining's [...] alternative plan follows:

The company shall agree to lease the completed section of the Frankford Elevated Railway from Front and Arch to Bridge Street, for a period running until 1957, at a fixed annual rental of $600,000, and to give the same privileges as are accorded the company's lines in West Philadelphia. The company to agree to operate all extensions and other lines of the city's system upon terms to be settled by arbitration before the Public Service Commission. The city to furnish all funds necessary for the initial equipment of the Frankford Elevated ready for operation, the company to furnish all funds needed for additional equipment during the period oi the lease ; the city's rental to be considered as a part of the company's fixed charges and all matters pertaining to the service and fare to be regulated by the Public Service Commission, either directly or through a local board, as provided in the former agreement.

December 20, 1919.

On Nov. 14, City Transit Director William S. Twining of Philadelphia presented an extended report to the joint Councilmanic committees of finance and street railways, giving his reasons for opposing the leasing of the city's Frankford elevated railway to the Philadelphia Rapid Transit Company and the proposed amendments of the 1907 contract. In this report, Director Twining includes a discussion of the 5-cent fare situation in Philadelphia which has attracted so much attention recently. On this point he said, in part:

"Mr. Mitten declared before the Federal Electric Railways Commission in Washington that 'co-operative effort is here found adequate to overcome obstacles seemingly insurmountable elsewhere.' As showing evidence of such effort he has stated, 'passengers carried per trainman increased 120 per cent -- 1910 to 1919. Public patronage increased from 288 to over 400 rides per capita.' Number of trainmen employed decreased 15.6 per cent. Total passengers per annum increased 72.3 per cent. Maximum number of cars operated increased 17 per cent. Passenger receipts per revenue car-mile increased from 27.2 cents to 38.4 cents, or 42 per cent. If we analyze these data we find the key to the 5-cent fare.

"Let us take the 120 per cent increase since 1910 in passengers carried per trainman, which Mr. Mitten points out as showing efficiency of managemert and co-operation of the trainmen. This increase in Philadelphia can be ascribed to the following changes:

"1. Larger, more modern and inviting cars. The average number of seats per surface car operated in 1910 was approximately thirty-four. At present the average is approximately forty-seven and one-half, an increase of 40 per cent.

"2. Increase in average speed of cars from 8 m.p.h. to 9 m.p.h. This increase in average speed was accomplished by cutting down the lay-over time and running time, the skip stops, etc.

"3. Elimination of lines of light traffic, thus raising the average of the other lines. Some of these lines are Race and Arch Streets lines, Callowhill Street line and Green Street and Fairmount Avenue line. Besides the elimination of these lines, in many cases routes were shortened and free transfer privileges given in lieu of the former direct route. This device contributes to the reduction in the average rate of fare, upon whi.^h Mr. Mitten has laid so much stress in his recent statements.

"4. Arrangement of runs and tripper service so as to reduce the total number of trainmen employed to a minimum.

"5. Rerouting and turning back of lines and withholding of service so as to reduce car mileage to a minimum. The expense of operation and therefore the net income vary quite naturally with the number of cars operated and car mileage; therefore, if the service be deficient in any particular, the net income as reported will be higher than it should be...."

April 3, 1920.

Recommendations looking to the improvement of electric railway service in Philadelphia, Pa., were submitted to the City Council on March 30 by the Philadelphia Rapid Transit Company and by William S. Twining, director of city transit. Director Twining presented to the Council a report outlining a plan for the operation and equipment of the Frankford elevated line, now nearing completion. The company asked permission to establish a $6,000,000 equipment fund to meet the need for additional rolling stock.

Director Twining's program for the operation of the Frankford elevated calls for a 5-cent fare for a ride between any station on the present Market Street subway-elevated line to any station on the Frankford line, with free surface transfer privileges. Mr. Twining proposed two courses of action in the event that the company refuses to come to a satisfactory agreement. First, Mr. Twining suggested the city should petition the Public Service Commission for a peremptory order demanding the company equip and operate the new elevated, or, second, that the city should construct additional lines in the central business district to serve as a feeder for the Frankford elevated in its present headless [...] condition.

WOULD GIVE THIRTY- YEAR LEASE. In case the company agrees to operate the new line, it will, under Mr. Twining's plan, receive a lease from July 1, 1920, to July 1, 1957. A provision is inserted for cancellation by the city upon reasonable notice and upon fair terms. Mr. Twining's plan calls for an annual rental payment to the city of 4 per cent of the city's initial investment in the line, this sum to be increased by the interest charges on additions made by the city during the life of the lease. The rental would be a direct obligation upon the company and not contingent upon any other payment. Sinking fund payments on city bonds would not be included in the rental requirements.

The company's proposal to establish a $6,000,000 equipment fund, which took the form of an ordinance, was acccmpanied by a letter from W. C. Dunbar, vice-president in charge of accounting. Mr. Dunbar explained that the certificates to be issued would bear interest at 6 per cent annually, maturing in equal semi-annual instalments during a period of not more than ten years, and they would be secured by a lien on 1,500 surface and ninety-seven elevated-subway cars.

This proposed equipment trust certificate issue is required to finance immediate necessities and supply increased car-carrying capacity, said Mr. Dunbar. The financing of new lines and extensions is planned to be accomplished by the formation of new companies issuing first mortagage bonds to cover the cost of construction to be guaranteed by the P. R. T., which company will also be the sole owner of such nominal issue of capital stock as may be required. Plans for the issuance and sale of these bonds will be presented from time to time for the Council's approval. Mr. Dunbar said in part:

Pursuant to the specific provisions of the second section of the 1907 contract stipulating that upon the occasion arising for any additions or betterments to the lines. Dower or equipment of the Philadelphia Rapid Transit System, a communication shall be submitted by this company to City Council setting forth the necessity for such additions or betterments requiring adilitional capital and properly chargeable to capital account together with the estimated cost thereof and a plan of financing, we beg to advise :

1. That it is necessary each year to undertake substantial expenditures for the improvement and upbuilding of the physical plant to meet the increasing demands for transportation with new construction and equipment.

2. That in accordance with the uniform system of accounts for electric railways prescribed by the Interstate Commerce Commission and adopted by the Public Service Commission of Pennsylvania, expenditures are properly chargeable to capital account when incurred for new and additional property or when constituting a betterment as represented by the additional cost or value of track, power plant, car equipment or other facilities installed in the replacement of existing property.

3 That additional capital is required by the Philadelphia Rapid Transit Company in order to meet expenditures for additions and betterments to property actually incurred during the year 1919, and for additions and betterments necessary to be undertaken at this time.

4. That during the year 1919 the sum of $1,521,269.16 was expended for additions and betterments to track, power plant, car equipment and other property; that the sum of $1,000,000 was borrowed by the company on short term note in order to meet these expenditures : and that this obligation must be met by the issuance and sale of a marketable security.

5. That the sum of $2,400,000 is urgently required to meet the immediate necessities.

April 17, 1920.

Reports Give Statistics for Last Nine Years Deadlock Over Operation of Frankford Elevated Line New Capital Required. RECENT transportation history in Philadelphia in connection with the proposed lease of the municipally built Frankford Elevated Railway to the Philadelphia Rapid Transit Company is summed up in two reports just issued by William S. Twining, Director of the Department of City Transit, Philadelphia. Various proposals and counter-proposals have been made by the city and the company for the operation of this line by the company, the last proposal of the company, that it pay a nominal rental only for the structure, being withdrawn last November because of opposition to it in the Council.

Construction on the Frankford Elevated Line was begun in 1916 [...]

In the opinion of the Director of City Transit much of the difficulty which the railway company now finds in undertaking to carry out the rapid transit proposals of the city lies in the rentals which it has agreed to pay to its sub-companies, which even prevents the furnishing of adequate surface transportation facilities at present.

According to Mr. Twining, the company's management deserves great credit for its "skillful steering between the Scylla of increased fares and Charybdis of bankruptcy," but the limit has now been reached, and to provide the facilities urgently needed either the present fares must be increased or there must be a scaling down of the fixed charges. A diagram is then shown of the cost of transporting a passenger in Philadelphia from 1910 to 1918 inclusive and during the first six months of 1919.

COST OF TRANSPORTING A PASSENGER IN PHILADELPHIA. In commenting on this diagram the Director points out that during the first six months of 1919 the operating cost, including taxes, was 3.62 cents per revenue passenger and the fixed charges 1.5 cents, making the total cost 6.12 cents per revenue passenger. On the other hand, if the company's gross revenue for the period be divided by the number of revenue passengers it will be found to equal 5.39 cents per revenue passenger. The surplus available for dividends, support of new capital, reserve, etc., amounts to only 0.27 cent per revenue passenger, an amount declared by Mr. Twining entirely too small for the purpose. Continuing, he says:

"The mere fact that the cost of service at the present time is over 6 cents per revenue journey shows that on a free transfer basis the flat 5-cent fare would not alone meet the costs of the company. The company's 5-cent fare earnings are now supplemented by the of 3-cent exchange tickets, the revenue from freight, express, milk, advertising, etc., and income from other sources. . . . The diagram shows that since 1910 (except in 1916 and 1917) the average cost of carrying revenue passengers has exceeded 5 cents. The diagram also shows that the low point in operating expenses was in 1916, and that there has been a rapid increase in the item of cost per passenger since that time. The fixed charges have dropped from 1.92 cents to 1.50 cents per passenger since 1916, because very little new capital has been employed and because the "fixed charge" on earlier capital is a fixed sum, the aggregate amount of which has not been changed appreciably in recent years. As the number of passengers carried has increased nearly 30 per cent during this period, the fixed charges per passenger have naturally come down proportionately. Had the ratio of fixed passengers to operating expenses remained what it was in 1916 the cost per passenger would now be 5.54 cents and the company would be showing a deficit in place of a surplus."

In conclusion Mr. Twining says that the saving made during the last few years is to be attributed primarily to the minimum investment in new facilities, a course made possible by the "complacency" of the public under "heart-breaking" conditions.

According to the report, facilities required today to render adequate service will approximate $20,000,000 to be put in service immediately, and within the next ten years at least $50,000,000 more should be supplied. About half of the $20,000,000 of facilities needed immediately is represented by the Frankford line and one-half by necessary surface line extensions.

July 3, 1920.

[...] On account of the importance of securing service on the Frankford Elevated Line as soon as possible, I recommend that the incoming administration arrange as soon as possible for the authorization and sale of a bond issue of say $4,000,000, such to be applied primarily to the purchase of cars and equipment for this line to Bridge Street, and any surplus remaining to be made applicable to any of the general uses of the department in connection with the development of the adopted plan. Inasmuch as the equipment contemplated to be purchased out of this money is of a more or less perishable nature and subject to more rapid deterioration than the subway and elevated structures heretofore contemplated, I recommend that these bonds be issued for a term not exceeding thirty years, and as the period of construction will be short, I recommend that the interest and sinking fund charges be not capitalized during the construction period. [...]

July 3, 1920.

Call for Bids for Transit Bonds. Bids for the $4,000,000 city loan authorized recently by the Council of Philadelphia, Pa., for completing and equipping the Frankford elevated line will be opened on July 14 in the Mayor's office. The bonds will bear interest at 5 per cent per annum, the highest rate paid by the city for many years.

November 6, 1920.

In the building of the Frankford elevated railroad it was aimed to avoid placing the station stairs on the sidewalks. At all stations on this line a building containing stairways, control, toilets and waiting room has been built within the building lines on property taken for the purpose under condemnation proceedings. At the platform level there is a bridge from the station building to the platform. Such a station is located at Ruan and Church Streets. It is a rectangular building and control may be at either the street level or at the platform level.

May 28, 1921.

Frankford Lease Probably Best. Director Twining of the Department of City Transit, Philadelphia, Pa., at a recent hearing submitted to twenty-eight questions put by E. E. Ziegler, president of the North Philadelphia Business Men's Association, on the proposed temporary lease of the Frankford elevated and Bustleton surface lines to the Philadelphia Rapid Transit Company. The director declared that the lease as now drafted would not hold up the operation of the Woodland Avenue line and the Chestnut Street subway. He said further that the lease was in fact only a compromise, but that it was the best that could be arranged. Mr. Twining emphasized the fact that the lease under consideration would be rewritten after the Public Service Commission had determined on the Philadelphhia Rapid Transit valuation.

August 13, 1921

"L" Lease Negotiations- Philadelphia Rapid Transit Anxious to Operate New Line, but Seeks to Avoid Previous Mistakes. Conferences are being continued at Philadelphia over the operation of the Frankford elevated and so-called Bustleton line by the Philadelphia Rapid Transit Company. The attitude of the railway is that it is not willing to repeat the experience of 1918 in this same matter when the city and the company agreed to the terms of the contract only to have the Public Service Commission after a year's consideration of the matter deny approval to the lease. The company insists that a representative of the commission shall sit in at the conferences so that body may be thoroughly informed as to the angles which the negotiations take.

So much misstatement appeared following the conference on Aug. 1 that at the conference on Aug. 9 the railway set forth its attitude as a matter of record. The position of the company right along has been that it would operate the Rhawn Street extension of the Frankford "L" and also the Byberry extension of the Bustleton line, if desired by the city, but in such event the Department of City Transit, with the company's engineers, should jointly prepare the best estimate possible as to the cost of these extensions and the loss to be sustained from their operation; this being necessary in order to prevent later misunderstanding.

The Philadelphia Rapid Transit Company has argued against the city building its own powerhouses entirely for reasons of economy. Since the city is now to supply its lines completely equipped for operation, the attitude of the Philadelphia Rapid Transit is that the added investment should be determined and the increased obligation to be assumed by Philadelphia Rapid Transit in paying 5 per cent interest upon city investment should be figured out. A further estimate should be made in this connection, as of the latest date possible, to determine more closely the deficit, heretofore figured at $925,000, which Philadelphia Rapid Transit will sustain in the operation of the Frankford "L" line to Bridge Street and the Byberry line as far as Bustleton.

In short, the plan of the Philadelphia Rapid Transit contemplates the early operation of the Frankford elevated and Bustleton line, with free transfers between the Frankford elevated and surface feeder lines, the city to receive 5 per cent annually upon its investment, while the railway, in order to save the city an expenditure of $1,318,000, agrees to outlay $632,000 in enlarged facilities. This amount, added to the $925,000 deficit from opertion, makes a total of $1,557,000 to be overcome at the outset.

As a further help to a better understanding of the issues involved the railway has included in a pamphlet which it issued recently the correspondence and contract embracing negotiations up to the time of submitting the draft of the lease to the City Council on March 31, 1921, including the joint reports of city transit and Philadelphia Rapid Transit engineers.

November 5, 1921.

Elevated Lease Negotiations Broken Off. Mayor Moore, of Philadelphia, Pa., has terminated the negotiations with the Philadelphia Rapid Transit Company over the terms of a lease of the Frankford elevated line and has announced his intention to have the line operated by the city as a separate and independent unit of the city's transportation system.

The apparent hope of the Mayor is that the railway will see what he considers the error of its ways before the completion of the work and accept the idea of the city.

At present the points of junction between the elevated railways built by the city and that built and operated by the railway is separated only by a few feet. As one writer put it, however, the structures might just as well be a mile apart, for the distance is not one of inches, but dollars. As this authority explained, the Philadelphia Rapid Transit was willing to come in and operate the Frankford road, but not at a loss, and though the city administration consented to a lease containing a guaranty against it, the lease went into the discard when Council began amending it. The attitude of the company was that it should be indemnified for any loss in its operation or created by the diversion of traffic from the surface lines.

December 17, 1921.

Philadelphia, Pa. Sealed proposals for electrical equipment for the substations on Cumberland Street, for the Frankford Elevated Railway will be received at the Director's office. Department of City Transit, until noon Dec. 20.

January 21, 1922.

P. R. T. Offers to Bear "L" Operating Costs for First Year. President Mitten of the Philadelphia (Pa.) Rapid Transit Company, in a statement issued on Dec. 31, 1921, amended the recent offer made to City Councils and offered to bear the loss in operating the Frankford Elevated line for the first year, to pay to the city for the second year 1 per cent on the cost of the line, for the third year 2 per cent, for the fourth year 3 per cent, for the fifth year 4 per cent, and for the sixth year and after 5 per cent, should the agreement continue for that length of time. The Market Street line did not earn a 5 per cent return until the seventh year that it had been in operation.

The amendment also provides that the city deliver 100 cars to the Frankford elevated line and the Bustleton surface line, fully equipped and ready for operation.

The original proposal, to which these amendments are added, offers, as reported in the Electric Railway Journal for Dec. 24, 1921, free transfers between the Frankford elevated and all connecting cross-town surface lines north of Arch Street. Free transfers will be continued between the Market Street elevated and connecting surface lines. The fare on the line between Bridge Street, Frankford, and Sixty-ninth, West Philadelphia, will be 7 cents cash or four tickets for 25 cents. Free transfers will be given between Bustleton line and the Frankford elevated, but an additional 7-cent cash fare or four tickets for 25 cents will be charged between Cottman Street and the present terminus at Bustleton.

The amendments are based upon the continuation of the present fare, but the unamended proposals, providing for a payment to the city of 5 per cent, were built on the basis of a straight 7-cent cash fare.

The Public Service Commission has approved the clause in the proposal providing that the same rate of fare shall be charged on the Frankford line as on the other transit lines, and the clause which states that the city may terminate the lease, after the first five years, upon six months' notice.

This action by the commission removes all uncertainty as to the acceptability of the lease with those provisions. Only the rental question remains to be settled between the city and transit company officials.

In a review of the transit tangle directed to city officials and the public generally, Mr. Mitten as evidence of the good faith of the company cites that the surplus for 1921, which amounts to $1,800,000, or 6 per cent on the paid-in capital, has been used for improvements and not for the payment of dividends.

February 25, 1922.

Philadelphia, Pa. -- Sealed proposals for block signals and interlocking for the Frankford Elevated Railway will be received at the Director's office. Department of City Transit, until Jan. 31.

March 11, 1922.

Philadelphia, Pa. Sealed proposals for constructing signal towers and for furnishing and installing underground cables along the Frankford Elevated Railway were received at the Director's office, Department of City Transit, until noon on Feb. 28.

March 25, 1922.

Philadelphia, Pa. The Director of City Transit has announced that sealed proposals for "cable connections for Power Feed and Negative Return, Contract 644" and for constructing an "Addition to the Car Inspection Shop in the Bridge Street Yard, Contract 648" for the Frankford Elevated Railway will be received at the Director's office until Thursday, March 30.

April 15, 1922.

[Advertisement] READY FOR SERVICE. Some of the 50 large new all-steel cars going into operation on the Frankford Elevated Railway, Philadelphia, all equipped with ELECTRO-PNEUMATIC Westinghouse Electro-Pneumatic brake equipment (Schedule AMUE) is recognized as an essential factor in the successful operation of modern high-speed elevated and subway trains.

Representing the highest development of the automatic brake plus the feature of electric control, the Electro-Pneumatic brake provides for instantaneous and simultaneous application of all brakes throughout the train, insuring short, smooth station stops and the shortest possible stops in emergency.

These are features which vitally affect the entire system of modern train operation in congested centers.

Electro-Pneumatic brakes not only save money, they point the way to increased earnings as well.

Westinghouse Traction Brake Company, General Offices and Works: Wilmerding, Pa.

April 15, 1922.

Rejects Lease Plan-- Mitten Disapproves New "L" Draft -- Claims Rental Was the Only Issue Not Formerly Agreed On. President Thomas E. Mitten of the Philadelphia (Pa.) Rapid Transit Company has rejected the new lease plan formulated by Mayor Moore and recently submitted to the Council and the company. In a letter to the Mayor he said that he was not willing to discard the agreement reached after months of discussion. He said that at the Councilmanic meeting held on Jan. 9, 1922, all matters with respect to the lease were settled except the rental. Inclosed with the letter was a copy of the forjmer lease tentatively agreed on.

It seems to be the general belief that Mr. Mitten will stand by the proposal assuming all operating losses during the first year of operation and then a graduated scale of return to the city amounting to 5 per cent in the sixth year of operation and thereafter. It is reported that Mr. Mitten's letter was entirely unsatisfactory to the Mayor.

The latest proposal by Mayor Moore on the operation of tne Frankford Elevated line by the Philadelphia (Pa.) Rapid Transit Company was forwarded to the City Council on April 6, thus renewing the interrupted negotiations for an agreement on the management of this line. As was commented on editorially in the Public Ledger there is encouragement in this communication in that the Mayor does not stress the independent operation of the line but rather the importance of an "agreement with the Philadelphia Rapid Transit Company and the unification of the service under one management."

The outstanding feature of the new draft is the change in the rental clause. The original proposal contained a clause for a 5 per cent rental from the beginning of operation. The Mayor now recommends a sliding scale of rental commencing at 2 per cent on Jan. 1 next and increasing by increments of 1 per cent per annum until the maximum of 6 per cent is reached in 1927. A 1 per cent payment plan had been suggested by T. E. Mitten, president of the Philadelphia property. The proposed agreement is to be permanent or until 1957, when the 1907 agreement also will expire.

CHANGE IN RENTAL SUGGESTED. An important feature of the Mayor's letter is the fact that the city should share in the company's profits above the 6 per cent mark, remarking that the same treatment that is promised to stockholders should also be extended to the city. The new arrangement includes the establishment of a depreciation fund to take care of replacemens necessitated by the wear on the city-owned cars to be used on the northeast line. The Mayor likens his draft to the one of March 31, 1921, in that no attempt is made to stipulate the rate of fare. In conclusion the letter said:

If this matter can be closed at an early date it is proposed immediately to bring to the attention of your body the question of extension now agitating certain sections of the city where car riders are asking for increased service. These extensions include an arm of the Frankford L, to provide high-speed service for the northern district of the city ; also the Roosevelt Boulevard and cross-town lines, all of which are contingent upon the operation of the Frankford L.

In the proposal submitted by the Mayor to the Philadelphia Rapid Transit Company Oct. 1 has been set as the date when the Philadelphia Rapid Transit Company will begin operation of the Frankford line. The line will be given rent free until Jan. 1, 1923, when the new provisions of the lease will go into effect.

April 29, 1922.

Elevated Lease Reported Negotiated. At a conference at the Mayor's office on April 27 attended by Mayor Moore, Thomas E. Mitten, president of the Philadelphia Rapid Transit Company, and Richard Weglein, president of the City Council, an agreement is said to have been reached by which the Philadelphia Rapid Transit Company will operate the Frankford elevated line for the city. The rental terms which the company will share are 1 per cent in 1923; 2 per cent in 1924; 3 per cent in 1925; 4 per cent in 1926; 5 per cent in 1927. The operation of the road will begin Nov. 5 of this year.

Mayor Moore announced after the Frankford "L" conference that the lease agreement would terminate at the end of five years unless the city gives notice that it wishes the lease continued. In a statement the Mayor said President Mitten asked for co-operation of the administration and councilmanic forces of the city government in transit matters, and while assured of such co-operation it was pointed out that the city would reserve its rights under the 1907 agreement, the valuation proceedings and others of a legal nature.

It was also stated that the matter of extensions was discussed and it was announced that now that the Frankford "L" lease was out of the way, efforts would be made to extend the Philadelphia Rapid Transit System into sections of the city not now provided with service.

September 2, 1922.

Mayor Moore of Philadelphia and President Mitten of the Philadelphia (Pa.) Rapid Transit Company recently discussed plans on the construction of other links in the network of highspeed lines for the city. The date for opening the Frankford Elevated to the public has been fixed as Nov. 5. Once the line has been placed in service, the Mayor said he would authorize the preparation of plans for the construction of other high-speed lines and among the first consideration would be the Broad Street subway, for which $25,000,000 was available. Mr. Mitten promised his aid in the building of othet lines to care for the "present and coming needs of the city" and Richard Weglein, president of the City Council, pledged his co-operation.

November 4, 1922.

Feeder Lines Suggested -- President Mitten of Philadelphia Rapid Transit Outlines Plans for Feeders for Frankford Elevated. Thomas E. Mitten, president of the Philadelphia (Pa.) Rapid Transit Company, appeared before the transportation committee of City Council on Oct. 25 and laid before it plans for the construction of three new lines designed to furnish crosstown service in the northern end of the city and serve as feeders for both the Frankford elevated and the Broad Street subway when that link in the high-speed system is constructed.

The main features of the Mitten plan are:

The abolition of the tortuous Route 75 which now winds Its way from Ridge and Midvale Avenues to Frankford by way of Olney and Wyoming Avenues.

The construction of a line beginning at the Pelham carhouse in Germantown, along Chew Street, Olney Avenue, Rising Sun Avenue, Adams Avenue, Margaret Street over to Richmond. That line would tie in Germantown with the Frankford elevated.

The construction of another line that would begin at Twentieth and Wingohocking Streets, run eastward along Wingohocking Street to Wyoming Avenue to Unity Street and then to Frankford Avenue, where it would tap the Frankford high-speed line at Church Street station.

The building of a third route that would originate at Twenty-ninth Street and Hunting Park Avenue, traverse Hunting Park Avenue, Erie Avenue and Torresdale Avenue to the Frankford elevated. That line would connect with the Frankford elevated at the Torresdale station.

While no definite announcement was made to that effect, it was learned that Mr. Mitten proposes to have the lines act primarily as feeders for the Frankford elevated, and with that end in view, free transfers would be issued between the new routes and the elevated.

Will Consult Communities. Mr. Mitten announced that as further extensions are contemplated, the company would consult the residents of the neighborhoods affected before planning new routes.

Mr. Mitten came to City Hall ostensibly in response to a resolution introduced by Councilman McKinley requesting the company to run a line over Torresdale Avenue to Frankford. Mr. Mitten surprised the Councilmen by voluntarily offering to build the two additional lines.

An official statement said: To make possible early development of these proposed lines, co-operation on the part of the city in the matter of street opening and necessary bridging is essential, and to that end the City Council was invited to go over these routes with President Mitten and his engineers on Oct. 30, bv which time it is expected the P. R T. will have a double-deck bus at hand to be used for this purpose.

Mr. Mitten explained that none of the extensions would be self-supporting at the start, but would rather add to the cost of operation of the entire road. He added that service to the people was now the dominant note.

November 25, 1922.

Philadelphia's Rapid Transit System Is Nearly Doubled by Frankford "L". SINCE Nov. 5 an important section of Philadelphia, before that date rather isolated from the central portion of the city, has been enjoying rapid transit. The new line runs in a northeasterly direction from Second and Market Streets to the center of Frankford, passing through some of the most important manufacturing sections in the city. This increases by 88 per cent the rapid transit mileage in Philadelphia. The jubilation which marked the opening of the line and the heavy traffic which has immediately come to it testify to the transportation need that has been met by this new development. It was built and completely equipped by the city of Philadelphia and is the first part of a comprehensive rapid transit program. The subway running north on Broad Street from City Hall will logically be the next step.

There is no doubt that Philadelphia needs rapid transit and ought to be able to support a reasonable amount of it. At the same time the people of Philadelphia could not expect a privately owned railway property to finance such expensive transportation extensions as this one, unless there was reasonable prospect of a fair return upon the investment. The Frankford "L" appeared not to be a feasible undertaking from the Philadelphia Rapid Transit Company's standpoint, as it would not pay its way for many years to come. The only thing for the city to do, therefore, if it felt it must have this transportation, was to go ahead with the rapid transit program laid out and make up deficits out of taxes. This is an illustration of cases where the transportation needs of a community sometimes have to be considered from a standpoint other than that of financial return.

In Philadelphia the city also built and equipped a 6-mile surface line, as an adjunct to the Frankford "L," and turned it over to the P. R. T. for operation without payment of rental for a period of five years at least. In this case and with the new elevated line the whole city has made a contribution to the welfare of a given section, with a view to assisting in the equable development of all of its parts.

It would have been disastrous for the public if the city had been obliged to operate the Frankford elevated line as a separate unit, although provision was made for doing so in case agreement as to terms of lease could not be reached. The citizens would have had the service, but with city operation they would have paid two fares instead of having through service for one fare over the entire rapid transit route, the former rapid transit line being the property of the P. R. T. They would also have missed many other advantages that go with a unified system of transportation.

November 25, 1922.

P. R. T. Gets City-Owned Surface Line Free for Five Years. SIMULTANEOUSLY with the turning over by the city of Philadelphia of the Frankford Elevated line to the Philadelphia Rapid Transit Company for operation, the city also leased to the P. R. T. a new 6-mile surface line, connecting Frankford and Bustleton. This comprises double track in the terminal towns and single track with turnouts between. This line was built and equipped, ready for operation, with five standard Birney cars, made by the J. G. Brill Company, and it was leased without payment of rental for a period of five years in order to help in developing a promising residential part of the city.

In the well-settled parts of Frankford and Bustleton, permanent track with 9-in. girder rail and granite block paving was laid. The balance of the road, being largely in undeveloped territory, was constructed less perma- nently, although substantially. Here the track is laid with 80-lb. T-rail, in crushed slag ballast. A signal system of the Nachod C-D type was installed to control the operation of cars on the single-track sections of the line. A snow plow and 175 sections of snow fence, each 8 ft. long, were also provided as equipment for snow fighting.

March 15, 1924.

Plan Joint Station of "L" and Pennsylvania Railroad. Plans for connecting the New York division of the Pennsylvania Railroad with the Frankford Elevated Railway at Harrowgate were discussed recently by Pennsylvania Railroad officials and representatives of business organizations in the northeast section of Philadelphia. The business men outlined a plan to replace the present Frankford Junction station with a new structure at Kensington Avenue, thereby virtually linking the Pennsylvania's New York passenger traffic with the Frankford Elevated Railway. Vice-president C. S. Krick of the Pennsylvania Railroad said this would be expensive and difficult to do. A more practicable plan, he explained, would be to have the proposed new station at or near Erie Avenue, and to connect it with the Frankford "L" by a sidewalk for passengers.

November 1, 1924.

Will Reopen Stations. Following protests from residents of the affected sections, the Philadelphia Rapid Transit Company will reopen the northbound Frankford elevated stations at Berks Street, Church Street and Torresdale Avenue, closed some three weeks ago because of their poor patronage. In its Oct 27 issue of "Service Talks," the company points out that in 1923, to pay operating costs and city rental, the average carload per trip on the hould have been 86 passengers, but the actual records show that there were only 56. The far-riding population of Frankford has increased but slightly since 1922 and this increase has been largely drawn from other sections of the city served by the Philadelphia Rapid Transit lines. The company now operates almost as many street cars to the Frankford district as it did before the elevated line was built. In spite of the new high-speed service, the company states, the public demands the same street car service.

October 9, 1926.

Philadelphia Council Favors "L" Extension. A 30-year extension of the present lease of the city-owned Frankford elevated lines to the Philadelphia Rapid Transit Company, Philadelphia, Pa., was approved on Oct. 1 by the City Council by a vote of eighteen to two. The agreement with the Philadelphia Rapid Transit was sought by administration leaders with a view to relieving the borrowing capacity of the city for the amount of the Frankford "L" bonds. With this it is believed it will be possible to borrow the $5,000,000 needed to finance the Sesqui-Centennial.

The bill provides that the Philadelphia Rapid Transit Company in consideration of the extension of the lease of the Frankford "L" for 30 years shall pay $903,000 annually, which is the full interest and sinking fund charges on the $13,421,000 bonds. The amount represented by the bonds would be added to the city's borrowing margin if the Public Service Commission and the Court of Common Pleas give their approval. W. W. Roper, member from Germantown, and Clarence K. Crossan, counselor representing the northeast, voted against adoption of the ordinance. Criticism of the compact came from various sources, dealing chiefly with the "untimeliness" of extending the lease with negotiations for the new Broad Street tube still pending. C. Oscar Beasley, counsel for the United Business Men's Association, announced that a taxpayers' suit was contemplated to upset the granting of the lease. An amendment to the agreement providing for a recapture clause which would allow the city to recover the line upon six months' notice was offered in Council by Mr. Beasley through W. W. Roper, but it was rejected.

The Mayor said he felt the provisions of the agreement were fair and equitable to the city and, unless otherwise convinced, he would go ahead and sign the measure.

October 16, 1926.

Philadelphia Lease Signed by Mayor. Despite popular disapproval Mayor Kendrick of Philadelphia, Pa., on Oct. 13 signed the ordinance providing a 30-year extension of the Frankford elevated agreement with the Philadelphia Rapid Transit Company. His signature was affixed to the document following a meeting with members of the transit commission, four of whom were opposed to the negotiation of the lease. The Mayor said that he "about understood the various sentiments of the commission members" and would not call for a vote on the question.

Alva B. Johnson, who represented the chamber of commerce on the commission, filed a report declaring his objections to the lease negotiations at this time. He recommended that the ordinance should not be signed and should be returned to the Mayor by the Council with the request that it be included in a new agreement to cover the entire transit properties. Charles B. Hall, president of the City Council and sponsor of the elevated agreement, declared that the funds released by the new agreement probably would not be used to meet the Sesqui expenses. It was charged that the lease had been amended to make available $5,000,000 for payment of the Sesqui deficit.

Under this new agreement the Philadelphia Rapid Transit Company will make an average annual return of $780,000.

November 6, 1926.

Claims Philadelphia Loss $4,000,000 in "L" Lease Terms. The Pennsylvania Public Service Commission considered a list of objections in City Hall, Philadelphia, on Nov. 4 to the proposed 30-year extention of the Frankford Elevated lease. Harold M. Evans, a former member of the Public Service Commission, acting as counsel for the City Club, pointed out that under the proposed amendment of the Frankford lease the city would receive in rentals from the Philadelphia Rapid Transit Company nearly $4,000,000 less than the total rentals payable under the original lease, if extended. There were many lively tilts at the hearing. Former Mayor Moore, who appeared as a witness, declared that the extension of the elevated lease to the Philadelphia Rapid Transit Company was a mere surrender by the city of its rights. City Solicitor Gaffney, President W. K. Myers and H. M. Evans argued over the difference between "equal to" and "equivalent to." At the close of the hearing Commissioner Beamish said he desired Mr. Myers to furnish at the next hearing, on Nov. 18, an explanation of what the Philadelphia Rapid Transit Company meant by "equal to" and "equivalent to" in reference to interest charges on city bonds.

The Mayor's recent approval of the "L" extension lease and the terms embodied in that agreement were referred to in the ELECTRIC RAILWAY JOURNAL previously.

November 20, 1926.

City Officials at Odds Over "L" Lease Renewal. An array of facts and figures was presented on Nov. 18 to the Public Service Commission of Pennsylvania at the second hearing on the position of the city of Philadelphia and the Philadelphia Rapid Transit Company for approval of the 30-year extension of the Frankford Elevated lease.

The hearing was preceded by a controversy in the press between City Solicitor Gaffney and City Controller Hadley, the latter calling the amended lease "unnecessarily unfair" and pointing out that, on July 1, 1957, when the proposed 30-year lease would expire, the P.R.T. would owe the city $3,706,000. He offered a substitute amendment in which the payments in the last ten years are increased each year by an amount that will make up the $3,706,000. In this way, he declared, the city will actually have the excess due from the P.R.T. at the end of 1957.

Controller Hadley also maintained that the Frankford "L" is not unprofitable as the P.R.T. claims and declared that his "audits for 1923 and 1924 show the receipts were $2,031,534 and the direct expenses in the same years were $317,671."

Thereupon, City Solicitor Gaffney took issue with Mr. Hadley's pronouncement that the lease was "unnecessarily unfair," accepted his analysis of the proposed P.R.T. return and then pointed out that the aggregate, if correctly applied, meant $635,000 more to the city than would be due if the present rental scale was continued until 1957. He maintained that Mr. Hadley's substitute amendment would be unfair to the P.R.T. in that the company was entitled to use the money during the final ten-year period.

Mr. Hadley's attack on the amended lease, regarded in the city hall as a blow at the administration's plan speedily to execute the new lease so that borrowing capacity tied up in elevated bonds could be released, prompted Mayor Kendrick to declare that "Mr. Hadley's statement came as a surprise" to him and that he stood "solidly behind City Solicitor Gaffney and his legal advice."

Thus matters stood on the eve of the second Public Service Commission hearing.

Reference to the first hearing appeared in ELECTRIC RAILWAY JOURNAL, Nov. 6, 1926, page 858.

December 4, 1926.

"L" Lease Hearings to Reopen. An investigation into the figures compiled by the Philadelphia Rapid Transit Company, Philadelphia, Pa., in support of the city-company petition for approval of the Frankford elevated lease was begun in Philadelphia on Nov. 26 by B, F. Morgal, chief of the Public Service Commission's accounting bureau. He has been directed by the commission to aid counsel for certain objectors to the 30-year extension of the lease for the city-built line, in computing exact operating costs of the elevated. The commission announced that hearings would be reopened on Dec. 9.

Opponents of the city of Philadelphia lease with the Philadelphia Rapid Transit Company for 30-year operation of the Frankford elevated line engaged Milo R. Maltbie recently to aid in the fight being waged against ratification before the Public Service Commission. Mr. Maltbie, a utilities expert of New York, headed the commission named by Mayor Moore to plan a comprehensive system of high-speed lines for Philadelphia. When counsel for the P. R. T. and for the Northeast Chamber of Commerce, City Club and United Business Men's Association met on Nov. 29 to thresh out certain data which had been requested by the commission, two of Mr. Maltbie's assistants appeared at the conference. They are George E. Goldwaithe, engineer, and Francis T. Mylott, accountant. Edward E. Roberts, engineer, representing the United Business Men's Association, also was present.

February 12, 1927.

Final Arguments on "L" Lease. The Public Service Commission of Pennsylvania on Feb. 7 took under final consideration the application of the Philadelphia Rapid Transit Company and the city of Philadelphia for approval of the 30-year Frankford elevated and Bustleton surface line lease. While the city and the company made almost identical requests for approval of the lease, opponents contended the lease would work a hardship upon the city, the taxpayers and the car riders.

City Solicitor Gaffney said the lease as it is drawn is only an amendment of one approved in 1922 by the commission. Instead of the graduated plan of paying an. annual percentage up to 5 until 1957, the company under the new lease will pay the fixed charges, including sinking fund, interest and state tax and an amount equal to that contemplated by the 1922 lease.

C. Oscar Beasley, appearing for the United Business Men's Association, said the car rider and taxpayer would pay for the "L" and continue to pay. Harold Evans, representing J. Henry Scattergood, a former Public Service Commissioner, who has always been an enemy to the lease, also argued against the "L" lease approval.

April 16, 1927.

Rapid Transit Operating Agreement Talk in Philadelphia. Thomas E. Mitten, chairman of the board of directors of the Philadelphia Rapid Transit Company, Philadelphia, Pa., is willing to enter into negotiations with the city for leasing the Frankford Elevated Railway and the Broad Street subway jointly.

This fact was made known by Mr. Mitten in a letter sent by him to Mayor Kendrick in reply to the Mayor's inquiry as to the best terms the P.R.T. could offer to the city for operation of the Frankford Elevated Railway after the expiration of the present lease.

Under the original Frankford L agreement, which was dated May 5, 1922, the term of the lease was fixed for five years, beginning Nov. 5, 1922, and expiring Nov. 4, 1927, with an option reserved to the city, but not to the company, to extend the term to July 1, 1957, by notifying the company to that effect not later than six months prior to the expiration of the five years term. That is, the city must notify the company of its intention by May 5, 1927, which is just about a month off. In order to decide what the city shall do in the matter Mayor Kendrick about a week ago wrote to Mr. Mitten, reminding him that May 5 is rapidly approaching, and requesting him to state the best terms under which the company would continue to operate the Frankford L in view of the fact that the proposed amended L lease had not received the approval of the commission.

There has been a decided opinion that the city should negotiate with the P.R.T. for an agreement that would embrace both the Frankford L and the Broad Street tube, which will soon be ready for operation. On the other hand, some persons are inclined to favor separate agreements for the two lines.

Unballasted Track Gives 50 Per Cent Lower Maintenance Cost

Electric Railway Journal · Vol. 48, No. 12 · September 16, 1916 · pp. 481-483.

PHILADELPHIA SUBWAY TRACK - VIEW SHOWING FOUR-TRACK TUNNEL

By WILLIAM S. TWINING, Director, Department of City Transit, City of Philadelphia. The author of this article was chief engineer of the Rapid Transit System in Philadelphia at the time that the subway in that city was constructed, and it was under his direction that the novel method of track construction there adopted was employed. It is interesting to learn that during nearly ten years' of service very few renewals have been found to be necessary and that no defects have developed which would suggest any desirable changes in the methods of construction.

At the time of the installation of the track in the Philadelphia (Pa.) subway in 1907 there was a great deal of interest manifested in the work owing to the fact that a new type of construction was installed. After nearly ten years of severe use this construction has given an excellent service record. Accordingly, the figures given below, showing the total yearly cost of this track construction as compared with the cost of ballasted track subjected to same service, are of value and interest.

The installation of track was described in the Street Railway Journal in the issue of Feb. 16, 1907, and further details were given in the issue of May 4, 1907, but for the benefit of those unfamiliar with this type of roadbed a brief description follows:

The construction comprises two 12-in. 20-1/2-lb. channels under each rail, the channels being spaced 15 in. back to back, with two 15-in. 33-lb. channels as permanent spacers. This steel work is assembled in the shop in 30-ft. lengths, then placed in position in the subway and accurately surfaced and aligned by attaching the rail thereto with temporary long ties spaced at intervals of about 15 ft. The channels are then embedded in concrete to the height shown on the accompanying illustrations. The concrete is brought to a true plane about 3/4-in. above the channel flanges to afford a bed for the ties. The ties are 6 in. x 10 in. x 2 ft. yellow pine, surfaced to precise thickness and placed on the concrete at intervals of 2 ft. They are anchored to the channels by 3/4-in. x 8-in. bolts passing through the ties (head up), the holes for this purpose having been previously provided in the flanges of the channels. After the ties are in place the rails are accurately aligned and fastened to the ties by means of screw spikes and cast-iron clips. The rails used are 90-lb. A.S.C.E. Bessemer steel in 60-ft. lengths. The carbon content is about 0.55 per cent.

The first section of track was placed in operation in February, 1907, and has been in continuous use since that date, or about nine and one-half years. The same rail and construction throughout as originally placed is still in service with the exception of the rail on curves, and probably the rail on tangents will have a life of about a year and a half more. During this period approximately 3,500,000 cars have used the track, or a tonnage approximating 140,000,000.

The tracks on the Market Street elevated line immediately to the west of the subway were laid at the same time with precisely the same type of rail and similar joint plates. The elevated construction consists of 6-in. X 8-in. x 8-ft. ties on stone ballast with a depth of 5 in. to 8 in. beneath the ties. The rail on the elevated structure was in such condition in 1912 as to demand renewal throughout the entire section between Twenty-ninth and Sixty-third Streets. This was done late in 1912 and early in 1913, after a life of six years, and during 1912 and 1913 the greater part of the ties were likewise renewed.

As there is no ballasted construction on any of the subway tracks in this city, the nearest approach to a comparison of maintenance cost between the subway type of construction and the ballasted type is a comparison of the subway with the section of the elevated above noted, both sections having been subjected to precisely the same amount of traffic. They are constructed with rail of the same weight and quality, and the same type of joint plates and method of fastening rails to ties.

An analysis of the expenditures running through several years, after eliminating such charges as would be common to any type of construction, indicates a maintenance cost for the subway track of about one-half that of the ballasted track, or approximately $528 per mile per year for the subway track as against $1,056 for the elevated ballasted track.

The initial cost of concrete construction is estimated at $44,352 per mile, and the ballasted construction $24,288 per mile. In the ballasted construction the cost of a concrete sub-base under the ballast has been included. Basing an estimate on past experience we have placed the life of the rail in the concrete construction at ten years and in the ballasted construction at six years. As to the ties, we have no definite information as to how long untreated ties will last in the subway. The present ties are in first-class condition after nearly ten years of service, and for the sake of comparison we have placed the life at fifteen years, and the life of the ties in the ballasted construction at eight years. In both cases, of course, the timber is untreated. Basing estimates on these figures the results are, in round numbers, as follows:

| Concrete Construction | |

|---|---|

| Interest on initial cost ($44,352 at 5 per cent) | $2,218.00 |

| Sinking fund for tie renewals ($4,224 in fifteen years) | 192.00 |

| Sinking fund for rail renewals ($6,336 in ten years) | 496.00 |

| Maintenance | 528.00 |

| Total yearly cost per mile | $3,434.00 |

| Ballasted Construction | |

| Interest on initial cost ($24,288 at 5 per cent) | $1,214.00 |

| Sinking fund for tie renewals ($5,808 in eight years) | 600.00 |

| Sinking fund for rail renewals ($6,336 in six years) | 918.00 |

| Maintenance | 1,056.00 |

| Total yearly cost per mile | $3,788.00 |

There is therefore a difference of $354 per mile per year, or about 9 per cent, in favor of the concrete construction. In making this comparison, no reference has been made to the fact that the channels in the concrete construction provide steel of a cross-section of about 26 sq. in. for each track, which is used for return current purposes, in addition to the 18 sq. in. in the rails. The cost of return cable of an equivalent carrying capacity is thus saved.

It must be borne in mind also that the larger part of the repair work required on the elevated is performed in daylight, whereas the subway work is all performed under artificial light with the usual disadvantages incident to such work. Furthermore, a large proportion of the expenditure on the subway track was virtually inspection work, consisting largely of going over the bolts and screw spikes at frequent intervals to make sure that all were in good condition and to detect any weaknesses incident to a type of construction which had not been previously tried. With these facts in mind it may be safe to say that the difference between the maintenance cost of the concrete construction and the ballasted construction would be considerably more than as indicated above.

The object of the designers was to provide a track with a permanent substructure, to avoid the continuous and expensive maintenance due to ordinary ballasted construction, especially as such work would be required in the limited confines of the subway; to avoid vitiation of the subway air by the accumulation of foreign materials which could not readily be removed, and to make all wearable portions easily accessible for inspection and replacement with a minimum amount of labor and the least possible interference with traffic. After nearly ten years of service there is no hesitancy in saying that our aims have been fully realized, and in addition to a reduced maintenance expense a substantially greater life has been secured in the wearable portions.

The actual maintenance work so far performed in the subway aside from the inspection and the replacement of the rail on curves, has been the renewal of a comparatively small number of the short ties and the changing of a few tie bolts and screw spikes which had broken, probably from being set up too tightly. It is readily seen from the drawing that such renewals can be made with two or three men, as each bolt or each tie can be removed and replaced independently of any other.

There is ample room between rails for the storage of any material required for repairs or renewals, and practically no interference with traffic is necessary except, perhaps, single tracking for very short intervals during the period of rail replacements. A few hours at a time during "owl" car service will suffice for this operation.

The cleanliness of the subway is, of course, a very important feature. The floor is practically a granolithic surface, which can be cleaned either by flushing with water or sweeping with ordinary house brooms, both of which methods have been used effectively and to such an extent that absolutely no foreign matter of any description has been allowed to remain. The track bed at station platforms is swept up each night [...], and the other portions of the subway [...] at frequent intervals.

Finally it may be said that the ten years' experience with this construction have not indicated any defects that would suggest any desirable changes to this method of construction. Some time ago it was thought that should such construction be installed in a location where the conditions of water to moisture would tend to cause rapid corrosion of the exposed face of the channel, it might be desirable to construct a special channel with a depressed flange so as to have the anchoring flange entirely surrounded by concrete. The need of this has not so far been disclosed by our experience.

|

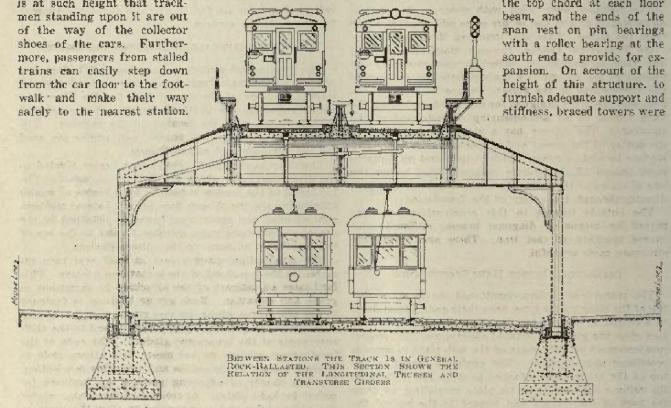

| PHILADELPHIA SUBWAY TRACK - Views Showing the Four Steps Followed in Laying Rails. Each rail is mounted on a series of wooden blocks which are held in position by 3/4-in. bolts passing through the blocks and the upper flanges of two 15-in. channels. The channels are spaced 15 in. apart by separators, and the space between them is filled with concrete so that the wooden blocks rest directly on the concrete. No ballast of any kind is used, so that the subway is very easy to keep clean. |

|

| TYPICAL CROSS-SECTION OF PHILADELPHIA SUBWAY SHOWING UNBALLASTED TRACK CONSTRUCTION |

New Cars for Frankford "L"